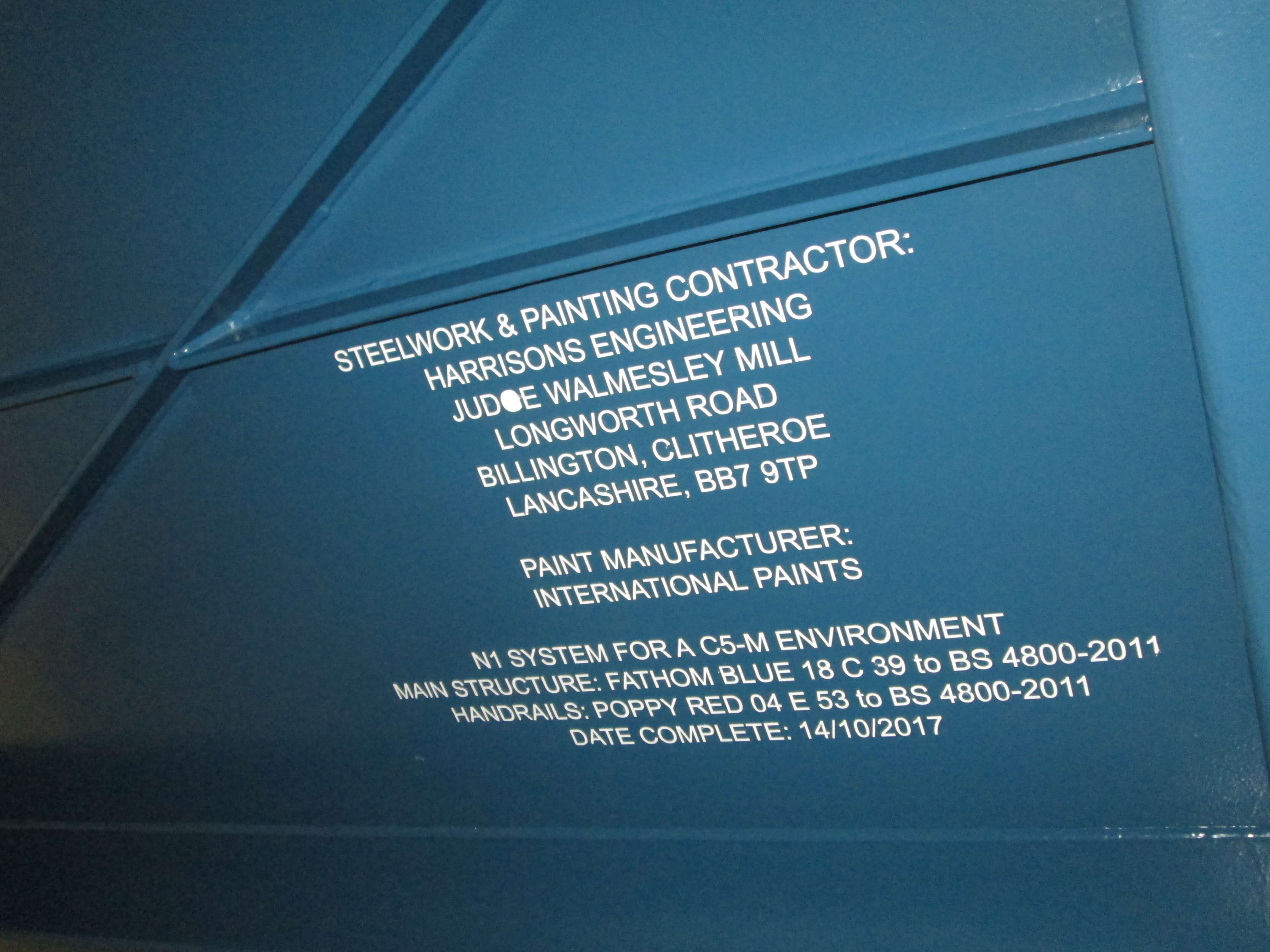

Blasting and Painting

An ICATS registered company with qualified applicators and ICorr certified Paint Inspectors to ensure the highest quality of workmanship.

Self-Contained Pressurised Blast Cabinet using Reclaimed Ali Oxide. Suitable for cleaning, removing light corrosion and other deposits, roughening, preparing surfaces and etching. Internal cabinet dimensions: 44″W x 26″D x 30″H

Grit Blasting

In our 300 sq.m (3,200 sq.ft)blast facility using SFEG AH-24 portable abrasive blast pots, our facility operates chilled iron grit and can achieve steel surface preparation grades from Sa1 up to Sa3 in accordance with BS EN ISO 8501-1: 2007. The blast medium is reclaimed and filtered using a grit recovery system.

Thermal metal spraying

Using Metallisation MK73-FS equipment our trained operatives are able to apply corrosion protection coatings of zinc, aluminium and zinc/aluminium alloys onto steelwork at thicknesses to suit your specification. Thermal metal spray is commonly used as an alternative to galvanising.

Industrial Coatings using Airless & Conventional spray

Utilising our spray rooms totalling 550 sq.m and Graco Merkur X48-1 high pressure airless spray units we are able to provide industrial coating systems to Network Rail and Highways Specifications and are approved to the National Highways Sector Scheme 19A for the corrosion protection of ferrous materials by industrial coating.